Heptagonal base is prepared...........dome panels arrive.......................construction of the wall.................pier lifted into place ................nearly complete. Bay to be fitted

A Pulsar Observatory 2.7m installation, operation and use.

Heptagonal base is prepared...........dome panels arrive.......................construction

of the wall.................pier lifted into place ................nearly complete.

Bay to be fitted

This fiberglass dome is made in the UK by Pulsar Observatories. They are currently the only supplier of domes this side of the Channel and have been around for several decades. There are some other very good options available in Poland, Germany, US and AU. These can be shipped over at additional cost. Alternative observatories such as the run-off-roof arrangement are simple to make at home. Buy a 6x8 shed and modify it. There are also manufacturers in the UK which specialise in the run-off-roof type. Occasionally ready made observatories come up second-hand (various designs). These would typically need to be dismantled, moved and refurbished. Ideal for someone with good DIY skills.

Order

date: 2019 December - deposit

paid (£1019) to Pulsar Observatories. Steve Collingwood FRAS is the CEO

On the Order: Full height with accessory bay, dome

and shutter drives including delivery and build by Pulsar.

Colour: SAGE green.

Base construction: Covid-19 restrictions and other

factors, prevented the base being laid in summer 2020.

Dome Storage: Pulsar

very kindly kept the dome in storage until we were able to install it.

Equipment : An EQ8 head purchased

Feb 2019 from MrOatley(1450), a Pulsar pier from Astronomia(250), a C11 from

from MrDaniel (1150)

2020 September: Local builder found to do the base, but not until mid-January 2021.

2021

Jan 18: Base is excavated and

shuttered: 3m x 3m with a 1x1x0.9m foundation for the pier. Two men + a mechanical

digger, 2" of hardcore added.

2021 Jan 18: We estimate 2cu m of concrete will

be used.

2021 Jan 22: The concrete is mixed on site as per Pulsar specifications and slopped in from wheelbarrows. A power condudite with pull-through was added,

Surface of the base: Zig-zag tamping gave a flat surface. The curring took about 2 weeks, and six weeks untill full strength.

Snow and ice: It turned cold over the following days. The surface was covered with tarpaulins, although the drying process created warmth (snow melted).

2021 Jan 27: Tarpaulins are removed. The base is 6" thick at the edges, and 2-3" above ground.

2021

Feb 23 : The base has been

wind-dried for a few days.

2021 Feb 23

:

Pulsar to deliver and construct the dome.

Pulsar no longer offer a construction service.

This is one of their last jobs.

Floor Kit:

I asked about a floor kit (rubber mats) but Pulsar no longer supply 2cm

thick rubber mats. One can get 1cm mats from Halfords etc .easily.

1cm thick Mats: I order 2 packs of 6 mats from Halfords for home delivery at £20. They can be fitted later.

Sealing the dome: Pulsar advise me that the sealant should be used when the base is "bone dry", but to apply Unibond PVA first (not supplied).

2021

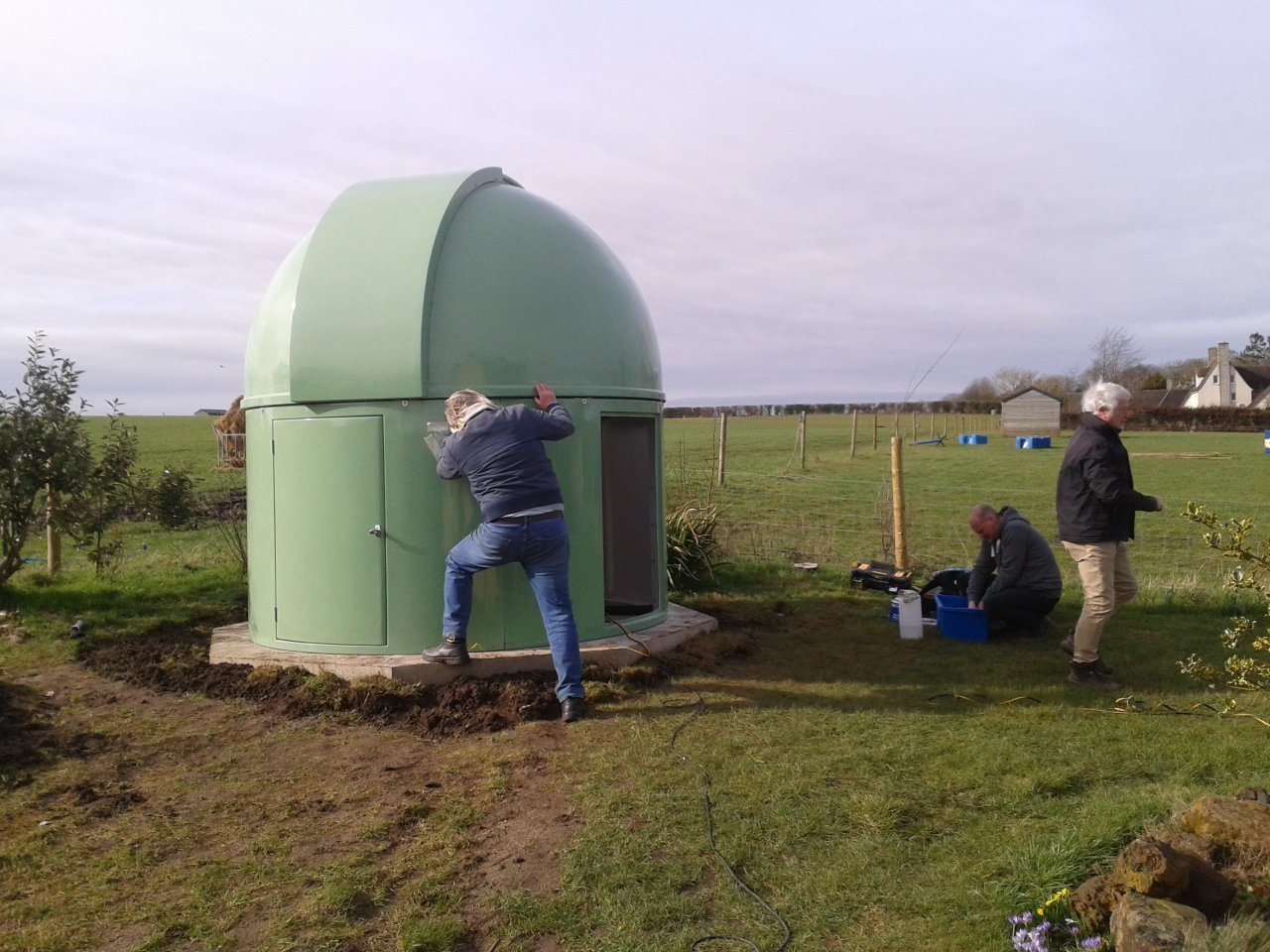

Feb 23 :

The Pulsar team arrive at 0930 after a long drive to start in sunshine, but

with a wind developing.

2021 Feb 23

: My Pulsar pier is bolted

down. I bought this a while ago. An offset to the South of 1-2" was added.

I had planed on 8". (Too much)

2021 Feb 23

: An 8" pier offset would

have given me more operational space near the bay, but would have restricted

the S horizon.

2021 Feb 23

:

The dome top required 5 persons to lift. Steve C said it was 20% heavier

for some reason. The dome sections are subcontracted.

2021 Feb 23

: Work is complete but the

walls are not sealed at the base. The dome drive is calibrated and demonstrated.

2021 Feb 23

: The dome needs to "settle"

and should not be used for "a while". The pier nuts were nipped up

about 1/4 turn (not torqued) 2 days later.

2021

Feb 25: An EQ8

adapter plate ( by Altair) was added along with six long M8

bolts for added height. The EQ8 was

offered up and aligned N-S.

2021 Feb 25:

The azimuth bolts are on the South Side of the Head (unlike EQ6pro on the North)

- I rotated the top plate and mounted the C11.

C11 on an EQ8 in the "home" position. An off-set counterweight

was fitted by the previous owner. I have added a pier extension using 6x M8

100mm bolts.

2021

Feb 26: Attempted to make first

observation but the EQMOD GOTO wasn't working. Incorrect encoder feedback. I

continued to Drift Align the polar alignment.

2021 Feb 26: The dome rotation stops in places.

Operation can't continue until the dome movement is assisted by hand !

2021

Feb 27: EQ8:

Advice from a user indicates i need to disable the EQ8 freedom-find encoders

in EQMOD setup. All is OK now on Windows 7 and 10.

2021 Feb 27: Dew is forming puddles on the dome

lip inside. Air is damp (T = -1C). Investigated the use of a dehumidifier which

i have borrowed.

2021

Feb 28: Did some imaging to

test the polar alignment - looking good. The dome rotation is making a loud

clonking sound and sometimes the motor looses grip.

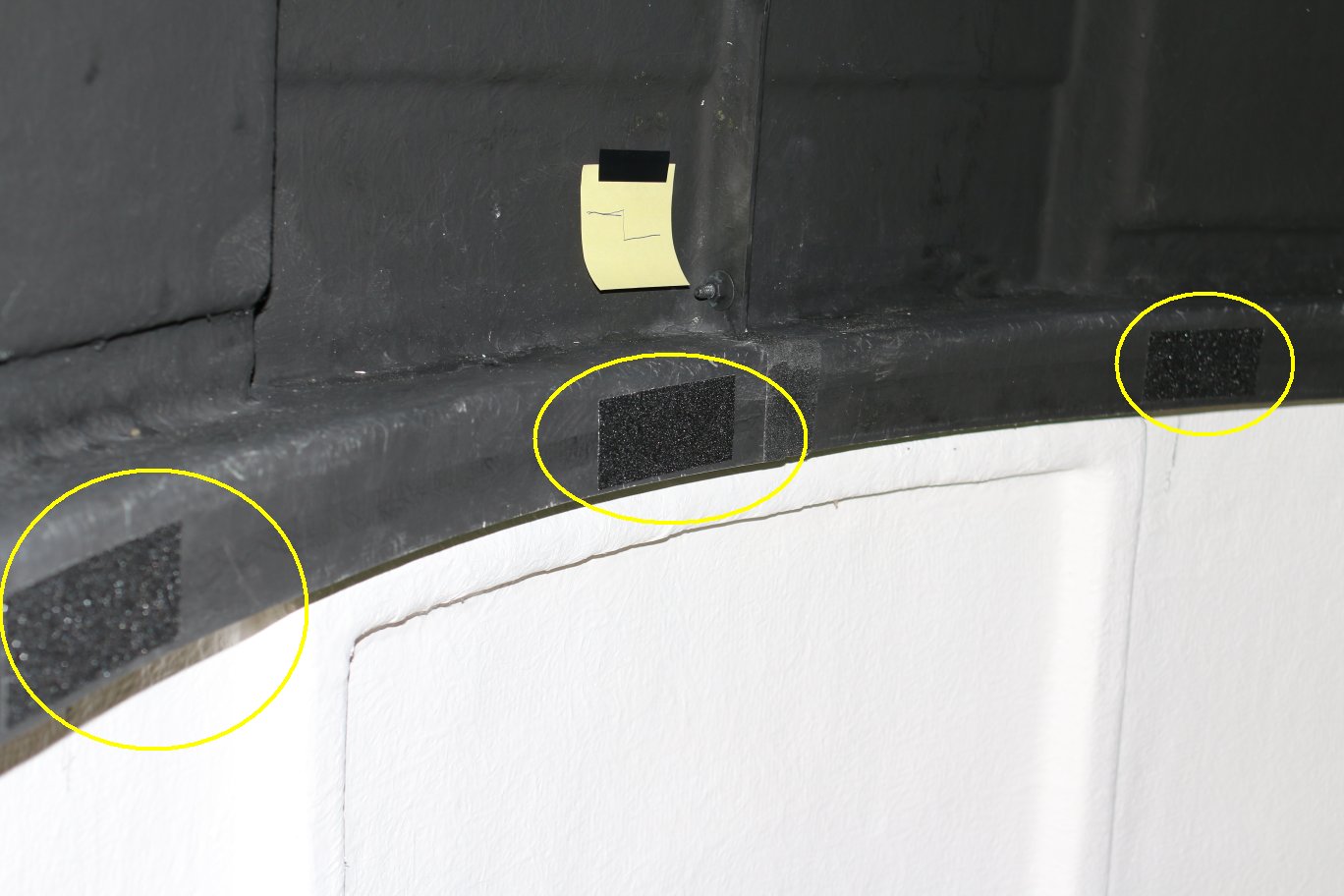

2021 Feb 28: Rain is expected next week, so

i start to run sealant around the base on the outside. Several days have been

dry. There a few big gaps to fill.

2021

Mar 01: Tweaked the polar alignment

via drift over 20min. Did some Ha imaging 30s x14. Nearly zero drift on the

stack - good!

2021 Mar 02: Completed the external wall-to-base

seal with a fat bead on the outside, and squirting in where the gap is wider.

One 300ml tube used up.

2021 Mar 03: Rain in the afternoon, and heavy during the night.

2021

Mar 04: Disappointed

to find a large puddle of water in the dome on the weather side (E). Inspection

indicated the wall joint seal was the cause.

2021 Mar 04: The wall joint was separated by 3

mm and rain trickles in. The white ground seal applied on the 2nd seems OK.

2021 Mar 05: Keeping the door open increases air circulation to dry out the floor. All four wall gaps were filled with clear bathroom silicone.

2021

Mar 06: I investigated the

"dome rotation seizure" and motor noise.

2021 Mar 06: When the friction drive is released,

I can push the dome around by hand. It is essentially free except where the

dome joints bump over the wheels.

2021 Mar 06: Feeling with my finger, one of the

dome sections is not aligned, and there is a 2mm lip between sections that wheel

has to move over.

2021 Mar 06: The lips comes into contact with two

wheels at the same moment because the sections and wheels are 90 deg apart.

The motor doesn't like this.

2021 Mar 06: When the friction drive is disengaged,

there is some side-to-side sliding of the dome of about 2cm. Take care not to

damage the induction charger.

2021 Mar 06: The battery has not been fully charged

since the extension lead to the house was removed. The power level meter indicated

charging is in progress.

2021

Mar 06: Does a full charge result in a "white or dark" display

icon? - I guess i will find out, but there is plenty of power to close the dome.

2021

Mar 07: Examined the dome wheel

arrangement. Looks like i get access to problem areas from outside the dome

where is can be lifted onto wood.

2021 Mar 07: When moving the dome i can slacken

off the friction driver and turn it carefully by hand. I can then engage the

tracking motor.

2021 Mar 07: I have chipped the entrance doorway

with my head (Ouch!). The doorway needs protection. I have ordered 2m of rubber

to cover the edges.

2021 Mar 07: The interior would benefit from some

sound insulation to stop the echo, and provide a minimal amount of insulation.

2021

Mar 08: I asked Steve about

the dome motors. All three are driven, two on the outside and one on the inside.

The pressure on the inside is adjustable.

2021 Mar 08: Given the power of the combined motors

I'm surprised the dome sticks.

2021

Mar 09: Rain and wind overnight

from S/SE. The floor is wet again on the side facing E near the door, but

no puddle. I think the wall joint seal worked.

2021 Mar 09: I now suspect the door. It is not

sealed to allow air to circulate. The door doesn't reveal a possible cause though.

2021

Mar 11: Wind and rain from

the SW. The floor is soaked. Rain is coming in between the dome and the wall.

Not weather proof.

2021 Mar 11:

I took a video from inside using my headlamp (internal power is not connected).

Will send to Steve C. for comment.

2021 Mar 11:

A prompt reply from SteveC expressing

shock says he will contact a Pulsar Owner who is in a similar rain-swept location.

He has a fix?

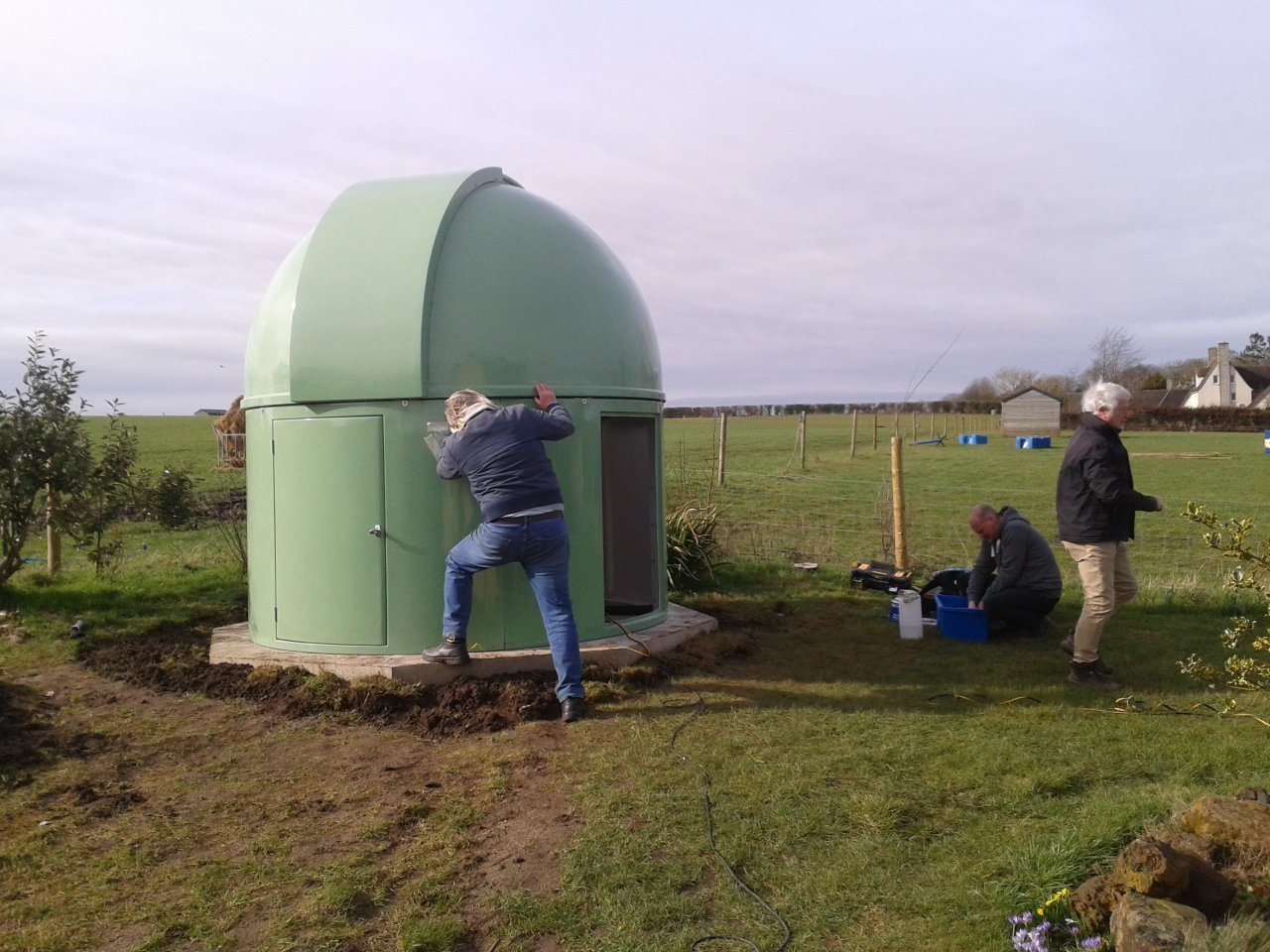

Rain water collecting on the inside...................flowing onto the floor

which had been dry.

2021

Mar 13: Received from Pulsar

an edging strip 8m x 35mm (x2) self adhesive to block rain blown in under the

dome. (KEPEAK Silicone Door Bottom...)

2021 Mar 13: After mopping up, air circulation

in the dome dries the floor off. The edging strip will not be fitted yet.

2021

Mar 16: Fitted a wooden panel (3/4" ply 1100 x 650mm)

above the power cable entry point. It will support 4 x double sockets.

2021

Mar 16: I made two supporting cross beams

in wood and aluminium plate to support the panel between the wall joint and

the accessory bay.

2021

Mar 17: Fitted

some U-Channel rubber edging strip to the doorway to protect the fiberglass

finish from shoes and heads. ( 2 x 1m ).

2021 Mar 17: Described as U50 U Channel (1638)

3-6.5mm panel x19mm high x 1.5-4mm wall (Commodity code 4008290090) £10.30

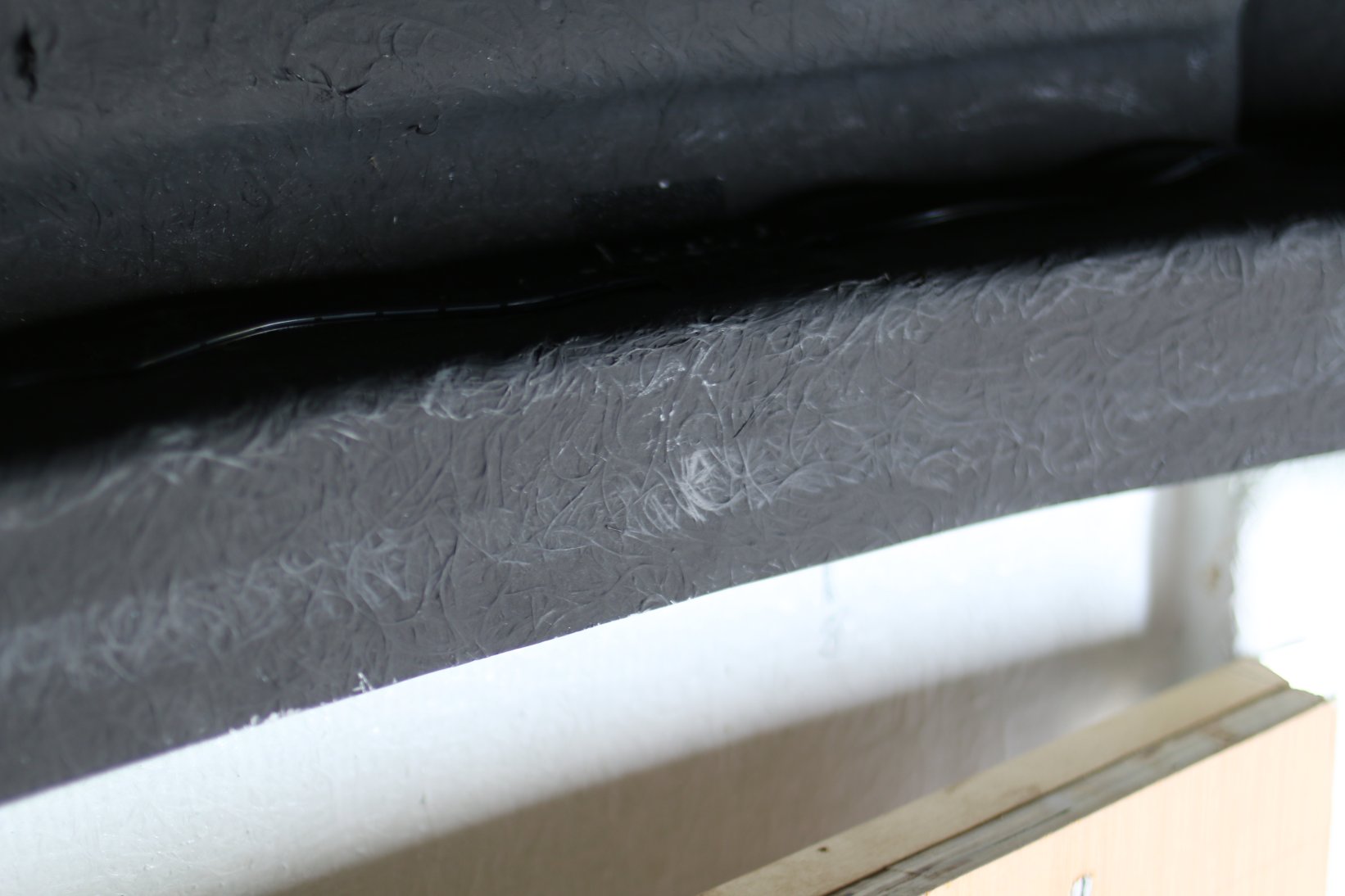

2021 Mar 17: Levered up one side of the dome onto

wooden blocks (1 x 3") to get finger access to the underside where the

joints were uneven.

2021 Mar 17: I

stuck some Black grip tape over the uneven areas where the free movement of

the dome was inhibited. Hopefully this will help the motor.

2021

Mar 19: Black grip tape over the dome joins (underside)

has smoothed out the "ride" but not fully - much better now i feel.

2021 Mar 19: The dome track that is gripped by

the inside motor is shinny, where the paint is rubbed thin, particularly the

areas where grip is lost.

2021

Mar 19: I

have stuck some grip tape over these areas to reduced the loss of traction.

I think it has worked - we will see.

2021

Mar 19: The

measured thickness of the dome and wall is 3 to 4mm.

2021

Mar 19: The

doorway area is much thicker at 5-6mm

2021 Mar 20: I discovered the shutter drive will close if the mains power is cut (loss of Blue-Tooth). A useful fail-safe.

2021

Mar 21: There

are gray areas where the inside motor looses traction. Here is an example -

and areas where i have added some grip tape

2021 Mar 21: Increasing the pressure on the drive

motor doesn't help. Its already quite tight.

2021 Mar 21: I connected a DIY

battery replacement cable/plug to replace the AC/DC adaptor. I now have a choice

of 12V or AC/DC for the dome motors

Rubbing point from the motor wheel...............Grip tape over

rubbing points.................2A 12V AC-DC adaptor supplied...............Home

made plug for 12 battery (for emergency!)

2021

Mar 22 : An electrician has connected the power cable through the trunking

to the fuse board. I have 4x double sockets.

2021 Mar 22 : The wall to base seal on the East

side doesn't fully seal. I added another layer of Bond

It over a 2ft area. My first bead was thin.

2021 Mar 22 : Bond

It (trade) GP200

White. Two were supplied by Pulsar. Here are the

details of use. I may need another tube

2021

Mar 30: The

weather strip sent by Pulsar, was added during a spell of warm weather. Should

keep out wind-blown rain.

2021 Mar 30: Power was installed earlier, and i

have made a shelf in the accessory bay to hold the laptop and other bits.

2021

Mar 31: There

was a difficulty with the Sidereal drive rate.The dome just accelerated and

the azimuth encoder was zero.

2021 Apr 01: Pulsar helped diagnose the problem

- simple - the dome motion encoder was not in contact the dome !

2021 Apr 01: I simply flicked the sprung loaded

mechanism with by finger and all was OK. Re calibration was suggested.

2021 Apr 01:

The azimuth is only off by a degree or so. I've left the

azimuth readout as-is for the time being.

2021

Apr 12: In

mid April a made an annular shelf to sit on the pier veins near the top. Stuck

on the underside is an LED strip light.

2021 Apr 12:

The LED strip is three small sections with 3 LEDS in each, connected by wires

and running off a 9v 1amp AC/DC adapter.

2021 Apr 12:

I bought a long strip of V-TAC leds for

lighting an office (warm white 3000K) with a 12v transformer. Just 10 leds on

9v is enough for the Obs.

2021 Apr 12:

The LED strip can be cut

with scissors into sections (in units of 3) and reconnected by soldering

on wires.

2021 Apr 12:

A second strip of 6 LEDs illuminates a work-station inside the dome. This is

run from a 9v PP3 in a switched battery box - ignoring the V-TAC instructions!

2021 Apr 16: Orion Optics (UK) 30cm F/4 is installed on the EQ8. The Lossmandy dovetail plate was bought from OO at AstroFest 2019.

2021 Apr 20: Bought some cable ducting from Screw Fix to tidy up wires across the floor.

2021

Apr 26: The

OO 30cm mirror was removed from the OTA and washed. - soapy tap water, de-ionised

water, and then IPA.

2021 Apr 26:

The mirror was first coated in 2006. Outwardly its good, but close inspection

showed microscopic dust and crud on the surface.

2021 Apr 26:

There was also a spider web in the tube near the mirror, and and some metal

swarf from a hole i drilled - now removed.

30cm before washing in 2021- It was previously washed in about 2016. I didn't

remove it from the cell.

2021

Apr 29: Some rain for the first

time in weeks. Not heavy, but there is an unsealed hole somewhere near the door

area allowing water ingress.

2021 Apr 29: I have bought

3 x 300gm tubes of GP200 sealant, and im going to push this into all the underside

rim gaps from the inside.

2021 Apr 29: My thinking is that a thick bead around

the outside (dome wall to concrete) is not enough to keep out water totally.

2021

Apr 30:

Picture: Observatory looking West. The home position

for the dome aperture (shown here) is pointing North. In this position the induction-

2021 Apr 30:

- charger is engaged and charging

the battery. There is a single accessory bay. The entrance door is visible from

the house.

2021 Apr 30:

Usually the dome is rotated to a

more southerly azimuth for use. Afterwards i sometimes keep the dome in the

last position used..

2021 Apr 31: EQ8: Over the last few weeks i experienced intermittent loss of connection to the mount. I use a RJ45 EQDIRECT/USB cable, EQASCOM and SkyMapPro.

2021

Apr 31: The difficulty was

I think caused by a bad USB plug - i re-arranged the cables a bit, and moved

anunrelated transformer further away. (Interference?)

2021 Apr 31:

The problem persisted without dropping any USBs, in particular COM6 for EQMOD

was still in service (see Device Manager).

2021 Apr 31: Reading some blogs, suggests the RJ45

connection at the mount was a possibility - it would explain a lot, but the

connection seemes OK.

2021 Apr 31: I plugged in the coiled SynScan cable,

and connected the Lynx cable via an RJ45 strait connector. This seems to be

successful. The joins are tight.

2021

May 01: A spare

ADM Vixen clamp is now used to hold a pan-and-tilt head attached with a tripod

1/4 20 bolt. I can now piggy-back a camera.

2021 May 01: I have added provison to adjust the

OTA ballence, by hanging some extra weights on it. I'll make a more permanent

fixure later on.

2021

May 02: Added

some more GP200 sealent to external areas. Then moved inside and sealed the

interior wall-to-concrete gaps. Two 300ml tubes used.

2021 May 02: The seal seems to have worked. We

had some force 7 gales and 45 degree rain for 12hrs, and the inside remained

dry.

2021 May 03 : At The top of the dome is a small

gap. When this gap faces South with lashing rain, a few drops can be felt bouncing

through - but not a problem.

2021 May 04 : Im now

happy with weather proofing - but i think this area of maintenance will be ongoing...

2021

May 14 : More

persistent rain for 24 hrs. It appears the door leaks water from the top although

im unclear how this occurs.

2021 May 14 : Its a small puddle so not serious.

I have bought some door seal which should prevent the water getting in at the

top and sides.

2021

May 20 :

Probem with Telscope control again. I thought this was fixed. I had turned on

the EQ8 power after the lapop and USB hub.

2021 May 20

:

Turning

on the mount first and then the hub/laptop seems to be a fix. No problem in

that order.(EQ8 first).

2021 June 01 : I have attached grip tape all arround the inside dome flange where the drive motor needs friction. This has smoothed out the drive tension

2021 June 10: I set up my 3" refractor with a Solar Wedge so that the partial eclipse could be viewed safely. The whole event up to mid eclipse was seen..

Eclipse awaited...........................First bite out of the Sun.........Photos with a telephoto lens............Eclipse progressing............Mid eclipse from the UK.

2021

July 01: I bought a second

(used) wireless gamepad controler from CeX. This is a Logitech F710. Its used

to fine adjust the telescope position.

2021 July 01:

Without it centering the object would be very inconvenient.

2021 July 01: If im a bit off target, i can also

use plate solve software. This takes an image and works out where i am pointing,

and makes a correction.

2021 July 01: One advantage is that

plate solving adds the coordinates (RA-Dec) to the image header - very helpful

for analysis later.

2021 July 09: Obs has been working well, but there has been a lot of cloud and rain of late.

2025 December.

During

the hot summer, i removed some of the older dome sealent at the base (inside

and out) and replaced with fresh. Also brushed more PVC onto the floor.

The 3m USB3 repeater cable was replaced last year - i think it failed. I used

a plain 3m USB extension for a while. I then suplimented this with a powered

USB3 hub from PiHUT by Waveshare: USB3 2-Gen1-HUB-2IN-4OUT

and a second USB2 from PiHUT for general connections.

I also fitted an auto focuser to the Celestron focus knob

This is the setup:

QHY174 fast frame rate + ASI120m guider + ZWO FilterWheel + ZWO EAF Focuser (0.5 m cables ) =>USB3 HUB =>3m cable => Laptop

Pulsar Dome + EQMOD (2m cables) =>USB2=>Laptop

Dome control with NINA: PULSAR DOME and EQMOD are now in slave mode. However my reason to instal NINA was as a close-down routine at the end of the night if im not there. A NINA sequence can be activatated at a pre-sellected time to close the dome shutter and home the scope. Very easy.

NINA must be running as Administrator if the other programs are in the same mode: - SharpCap4.1, SkyMapPro. Otherwise NINA doesnt connect to mount through ASCOM. Thanks to Robin Glover (of SharpCap) for this hint !